implant bridge with atlantis

As much as I like using my CEREC for implant restorations, the workflow for restoring a bridge is a little cumbersome. In order to restore a bridge from 19-21 using the chairside software, you need to scan the implants with Sirona scan posts, designate mutilayer single restorations for 19 and 21, split the restorations and mill just the abutment portion. You then need to either seat those abutments in the patient, pack cord, and scan them in as teeth in order to designate a traditional 3 unit bridge in the chairside software. The other option would be to take a physical impression on the implants, seat the abutments on that model and scan that back into the chairside software. If you have the premium software, you can designate a multilayer bridge and design it all together, but I've found those to be my hardest designs.

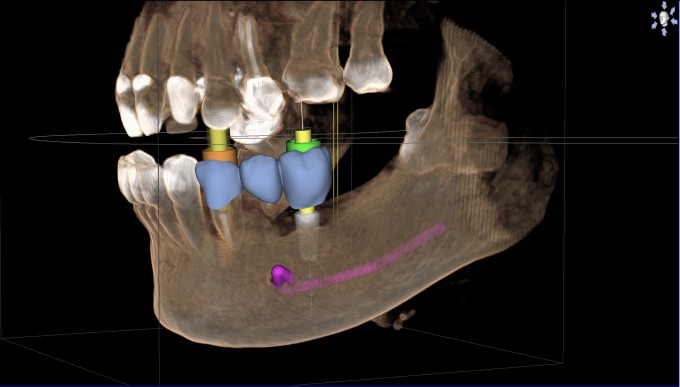

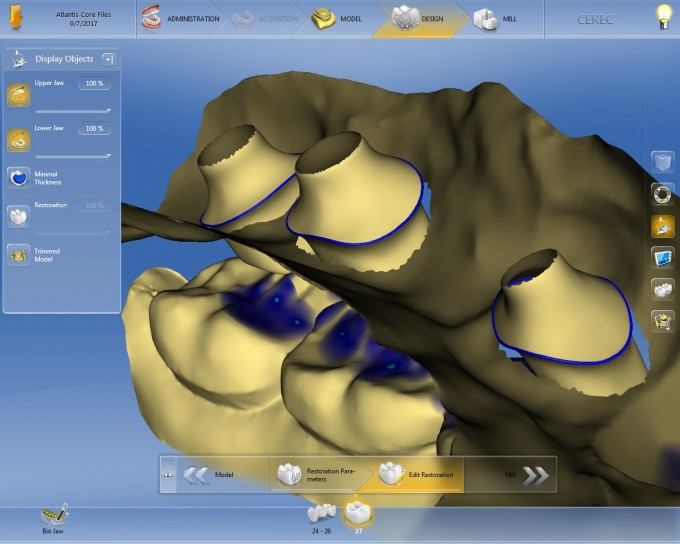

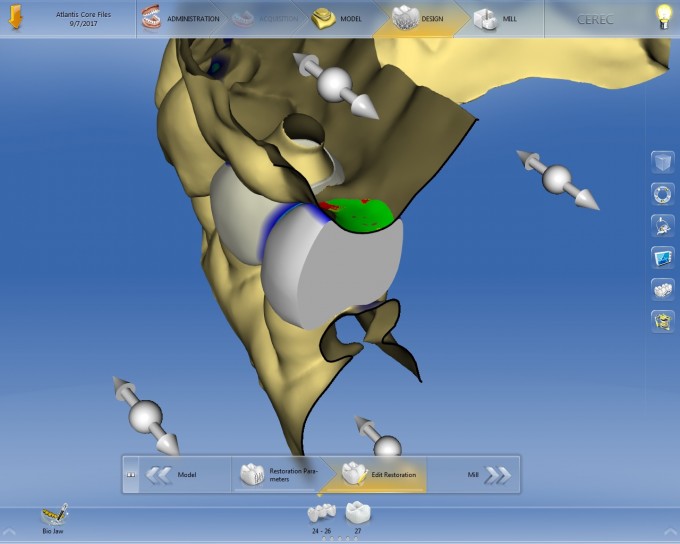

Now, I scan the implants with Sirona connect 4.5 using the Atlantis FLO scan bodies, that same day I approve the abutment design from Atlantis. By the next morning I have the core file of the abutments that I approved on a model that I can import into my chairside software and I design the traditional bridge. The next day, the abutments arrive from Atlantis. This saves me from either having to do a second scan appointment with the patient or from pulling out my old expired pvs material and doing a traditional impression.

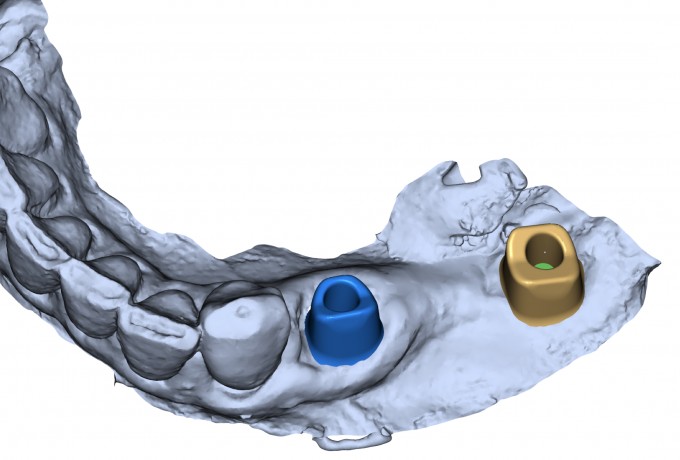

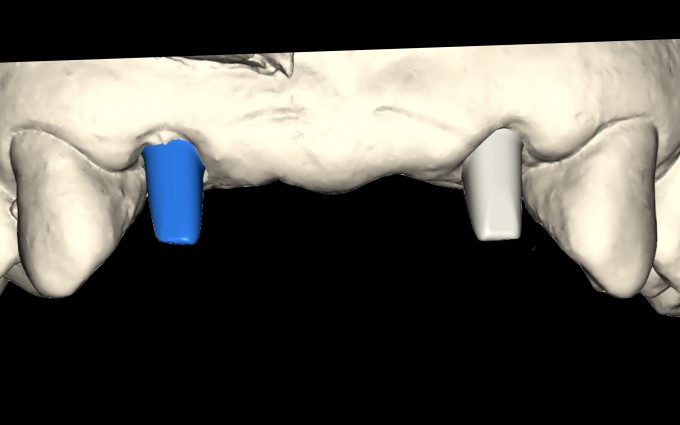

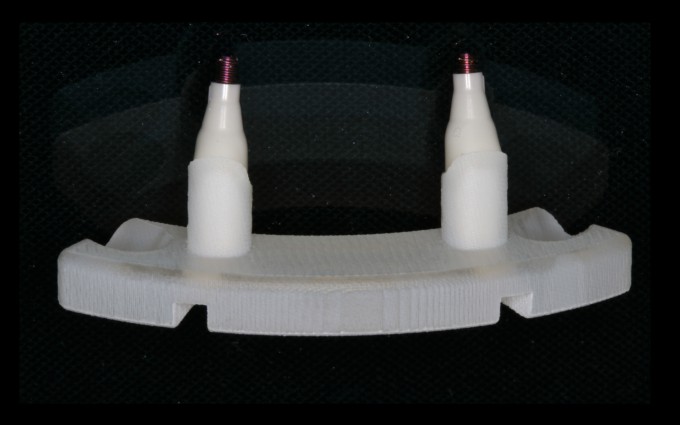

These are a few photos of the process:

They also send an .STL file if you want to print the model with the abutments.

I normally request an insertion guide for bridges, so that I can go directly to the mouth with the correct orientation.

In my opinion, this is an easier workflow for sure. The abutments cost me $150 a piece (for titanium) and about $40 for the zirconia bridge block.

Nice! Did someone mention a few weeks ago that dentsply was comping some scan bodies for this workflow?

On 11/8/2017 at 2:26 pm, Marc Thomas said...Nice! Did someone mention a few weeks ago that dentsply was comping some scan bodies for this workflow?

Fake news! I have ordered several IO FLO's, they cost 153.87 with shipping and taxes.

Daniel- how much time before submitting the case on Sirona-Connect and seeing the case on the AtlantisWeb Order site? I submitted a case this morning and still don't see the case on the Web Order site. Can't complete the order until the case is posted to their site. This will be a great work flow and nice to have Ti as a choice for custom abutments.

That's a pretty slick work flow. I have a couple multi unit cases coming up that I will have to use that for.

A couple of questions Dan.

1. Can the scan bodies be reused?

2. Does this work with any implant system?

Scan Bodies (IO FLO) are designed to be reused.

DS has a PDF listing the supporting manufactured. I can upload a copy tomorrow when I return to the office.

On 11/8/2017 at 5:36 pm, Steven Ozer said... Scan Bodies (IO FLO) are designed to be reused. DS has a PDF listing the supporting manufactured. I can upload a copy tomorrow when I return to the office.

Awesome thanks Steve

Excellent job Dan.

Did they print that abutment insertion guide? How much did they charge for it?

Here is the FLO compatibility chart, they are indicated for multiple uses (I was quoted several hundred). I know they are working on printing models for you, but with the .dxd core file they also send a zip file that has the .stl in it. You need to play with it a bit in meshmixer, but I just printed it myself for just the cost of the resin. The abutment insertion guide is free with zirconia, but I'm not sure the cost with titanium. It for sure makes it easier to seat multiple abutments, it has a screw access from the top that you can go directly to the mouth with.

On 11/8/2017 at 5:19 pm, Steven Ozer said...Daniel- how much time before submitting the case on Sirona-Connect and seeing the case on the AtlantisWeb Order site? I submitted a case this morning and still don't see the case on the Web Order site. Can't complete the order until the case is posted to their site. This will be a great work flow and nice to have Ti as a choice for custom abutments.

Did you get the email from Sirona Connect that the order was sent? It has always taken less than an hour for me to see it in weborder, I'd call if you don't see it in the morning.

On 11/8/2017 at 5:55 pm, Daniel Butterman said...Here is the FLO compatibility chart, they are indicated for multiple uses (I was quoted several hundred). I know they are working on printing models for you, but with the .dxd core file they also send a zip file that has the .stl in it. You need to play with it a bit in meshmixer, but I just printed it myself for just the cost of the resin. The abutment insertion guide is free with zirconia, but I'm not sure the cost with titanium. It for sure makes it easier to seat multiple abutments, it has a screw access from the top that you can go directly to the mouth with.

Dan,

As I mentioned in my email to you this morning, I was charged for everything. I was charged $360.00 for a zirc abutment, $25.00 for the insertion guide, $15.00 for the core file, plus sales tax and shipping brought the total cost to just over $450.00. Super slick process; the guides are amazing, the abutments fit perfectly, and using the core file makes crown fabrication a breeze. I don't want other Cdocs to open their invoice and have sticker shock like I did. I have been unsuccessful at getting any info or a return phone call out of DS or Atlantis regarding the special pricing mentioned by Darin in the webinar that cdocs are supposed to be getting. Hope this gets resolved, I have four more on the way!

dan,

Beautiful workflow, case, and presentation. Off topic here but the only thing I would change would be the pontic design....A ridge lap pontic design like that is relatively unhygienic from a periodontal perspective.

Farhad

Bruce,

Sorry for your difficulties with the pricing. Not making an excuse, but the whole process is so new that they're still working out the logistics. I passed your email from yesterday along to the people at Atlantis, and I know for a fact that they are addressing the pricing problems and will get this fixed. They honestly didn't think there would be much demand for zirconia, so the $150 special pricing is for titanium. Try not to get discouraged, I'm confident that this will all be addressed.

On 11/8/2017 at 10:36 pm, Bruce Herr said...On 11/8/2017 at 5:55 pm, Daniel Butterman said...Here is the FLO compatibility chart, they are indicated for multiple uses (I was quoted several hundred). I know they are working on printing models for you, but with the .dxd core file they also send a zip file that has the .stl in it. You need to play with it a bit in meshmixer, but I just printed it myself for just the cost of the resin. The abutment insertion guide is free with zirconia, but I'm not sure the cost with titanium. It for sure makes it easier to seat multiple abutments, it has a screw access from the top that you can go directly to the mouth with.

Dan,

As I mentioned in my email to you this morning, I was charged for everything. I was charged $360.00 for a zirc abutment, $25.00 for the insertion guide, $15.00 for the core file, plus sales tax and shipping brought the total cost to just over $450.00. Super slick process; the guides are amazing, the abutments fit perfectly, and using the core file makes crown fabrication a breeze. I don't want other Cdocs to open their invoice and have sticker shock like I did. I have been unsuccessful at getting any info or a return phone call out of DS or Atlantis regarding the special pricing mentioned by Darin in the webinar that cdocs are supposed to be getting. Hope this gets resolved, I have four more on the way!

https://www.cerecdoctors.com/discussion-boards/view/id/59788

We have not had any success with Atlantis for our implant bridges. The problem we are having is that the gingival height of the abutment that is milled is about 1-2mm longer than how we are designing it in their 3D editor. So we would design the bridge from the core file with nice 1mm subgingival margins, and the fit to the abutments to the bridge is great, except intraorally the margins are now 1mm supragingival, there is a huge space under the pontic, and the patient is several millimeters hyperoccluded. We’ve had three cases since June and so far Atlantis is a perfect 0/3. Our Dentsply Lab rep has not been helpful. Any insights from anyone? These are Astra Osseospeed TX. Is there a checkbox that I am missing?

Nice case daniel!

Alex: Can you post your core file for omeone to look at. I have had only success with astra tx abutments

Thank you Marko.

Alex, I too have only had success with this workflow. As Marko said, looking at the weborder design images along with the .dxd core file would be helpful. This is an example of a case I did for an anterior bridge, the weborder design images match up exactly with the intra oral clinical situation.

Kurt,

Click on insertion guide in the weborder :)

Seriously, it's not worth the time, but if you print the model, you could make an index to fit it out of acrylic or design something in meshmixer I guess.

I appreciate that there are individuals who’d look at the core file and try to help. But you’ll find there is nothing interesting there except a bridge design on their core file - whose digital abutment position does not correspond to what is milled. It’s quite frustrating the time and wasted blocks spent failing to get this to work. It’s surprising that everyone else seems to be having such an easy time with Atlantis, which is such a huge contrast to my experience. And it’s disappointing as hell that Atlantis reps ignore you and can’t (or don’t want to) help troubleshoot my issue.

Alex, I'm sorry you're having this trouble. Would you mind sending me a PM with the weborder number of this case? With your permission, I will forward it to the design manager at Atlantis along with the photos you've posted and see if they can figure out why you're having these problems.

Outside the mouth the margins were closed. But since the abutment gingival height was increased, any divergence in the implants themselves gets amplified and unless you have a very generous spacer to compensate for this the bridge won't seat completely. The most posterior implant is a single unit. It's margins were gracefully closed.

Daniel, I'll send you the weborder right away. These are the same photos (and tons more) that I've sent to my regional Atlantis Rep. The engineers performed an analysis and proudly reported that the abutments are within the tightest tolerances in the industry. And I agree, the abutments were milled very nicely. But it's the gingival height of the abutment that they keep screwing up for my cases and I don't understand why.

Unfortunately I haven't found a way to scan something like a gingival mask over the corefile. That would definitely show that the abutments are positioned coronally.

Marc, the marginal ridges were more or less on the same level, but I really didn't have a much better way to discern if the discrepancy was uniform. The imported core file does not allow any acquisition, so it was not possible to overlay and stitch the corefile with an intraoral scan.

the bite is a a separate issue,that we all can get when treating an arch without a posterior vertical stop, however it looks like the transfer or how they calculated the implant position, ie. the scan body that was input on their side, or something to that nature, like picking scanbody or scanpost incorectly effects the height of the platform is what is to blame, they would have to retrace their footsteps to find where that error came from. , best guess

Alex, the design engineer is on it but needs more info. Can you pm me your email so he can connect with you directly?

On 11/11/2017 at 5:25 pm, Daniel Butterman said...Kurt,

Click on insertion guide in the weborder :)

Seriously, it's not worth the time, but if you print the model, you could make an index to fit it out of acrylic or design something in meshmixer I guess.

I was thinking if we were doing the implant abutments and crowns in office, and wanted to 3d print an insertion guide.... :) Its sometimes hard with fat fingers to manipulate the implant crowns for say 18/19 on a pt with limited opening.

I was thinking we could do the implants in a second case and design the crowns splinted and use cad temp to create a guide, and then drill holes in it. It would be nice to be able to export the stl and create a guide in meshmixer and then print.

@Alex, I agree with Mark, something is amiss with how the scanbodies were inserted or designated similiar to the error that occurs when tibase or scanpost is miss-designated in the CEREC software. Obviously, they are using a different software to design, but it must be a similiar error.

I have not ruled out my own incompetence in the matter. Although if that’s the case, I am very consistently incompetent with whatever I am doing wrong.

- These are new Atlantis IO FLO scanbodies. Rules out damaged scanbodies.

- scanned as “crowns” to send via Sirona Connect. I believe that’s what the protocol requires in their user guide.

- flat side of scanbodies positioned towards buccal for accurate scanning as that’s the most important element.

- Fully inserting and correctly seating the scanbodies is about as easy as coloring inside the lines. Unlikely to uniformly screw up three times at once.

I just don’t know....

I’ve been looking at their website where you designate the implant system and sizes. I found it odd that astra osseospeed tx is listed twice for each size, redundantly. Once as just Osseospeed 3.5/4.0, and again as Osseospeed 3.5/4.0 (aqua). The same for 4.5/5.0 and 4.5/5.0 (lilac). It should not matter, but does it?

@ Alex,

I'm a bit confused. The photo looks like you are using screw retained with titanium abutments. I was under the impression that screw retained was only available in a Zirc connection.

Did you drill a hole in your restoration and cement outside the mouth to create a screw retained restoration?

Thanks,

Ed

@Edward

That’s correct. Designed a dimple in the software directly over the abutment access and drilled through it while in purple phase.