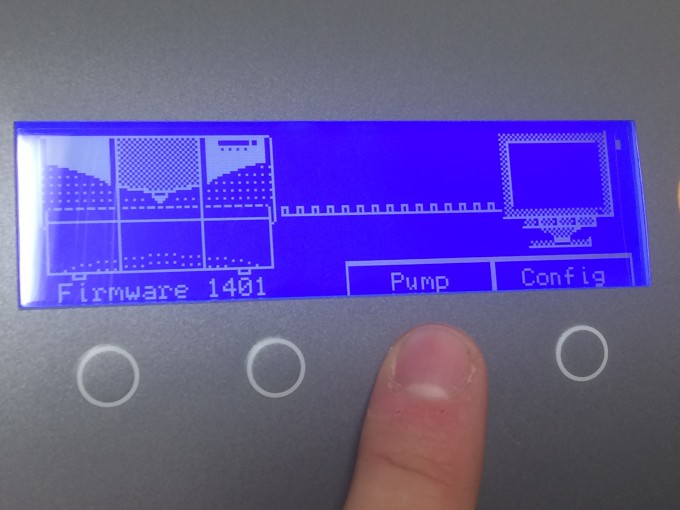

got a great MCXL maintenance tip from my patterson tech today.

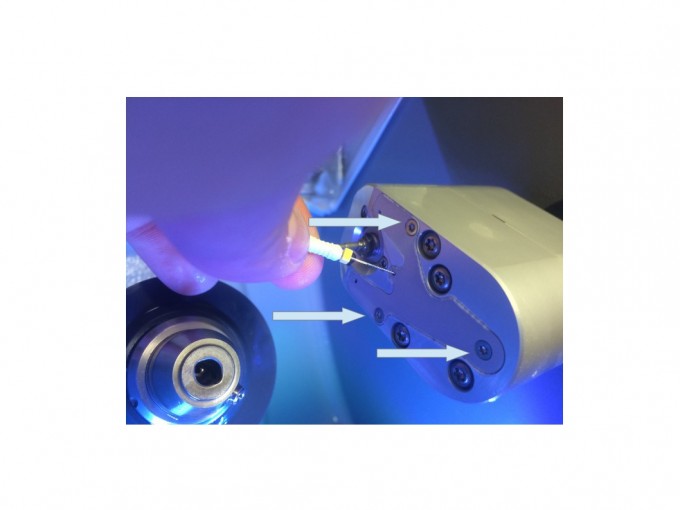

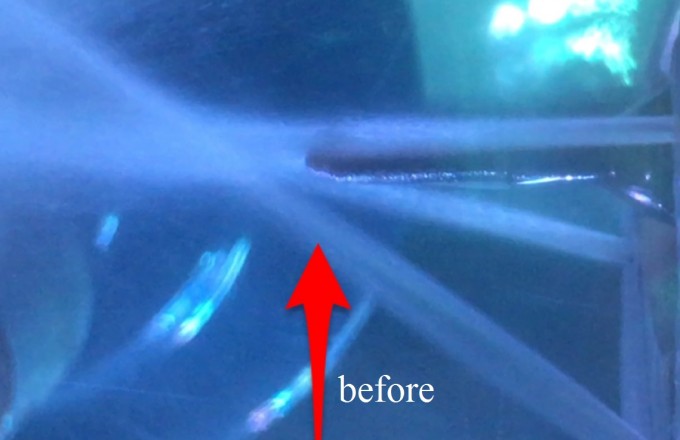

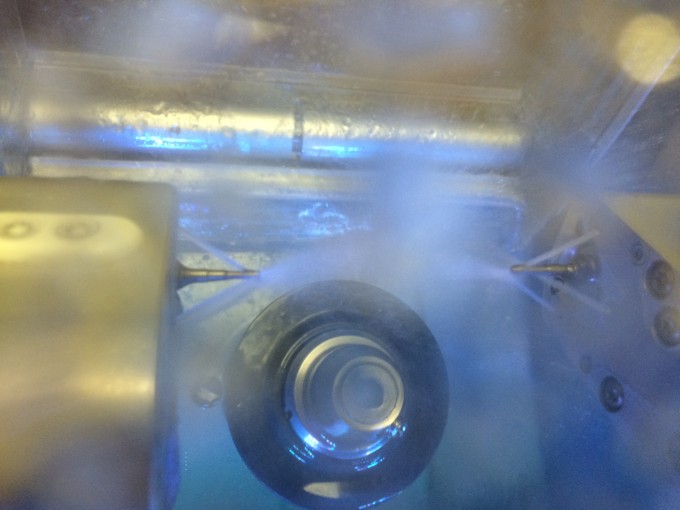

I just had my annual maintenance on my Omni and MCXL this morn. Patterson techs do such a great job when they come out. They really know the machine and give lots of great tips on maintenance for our daily routine. I got a good one today that I thought I would share. He told me that the water jets that shoot water to the tip of the burs had some clogs in them. For those that don’t know where the water jets are, this is a close up of the 3 small holes where water is aimed at the tip of each bur.

These holes can get clogged occasionally with some of the milling debris. If all 3 jets are not hitting the end of that bur, you are going to go through a lot more burs than you would like. Try these steps:

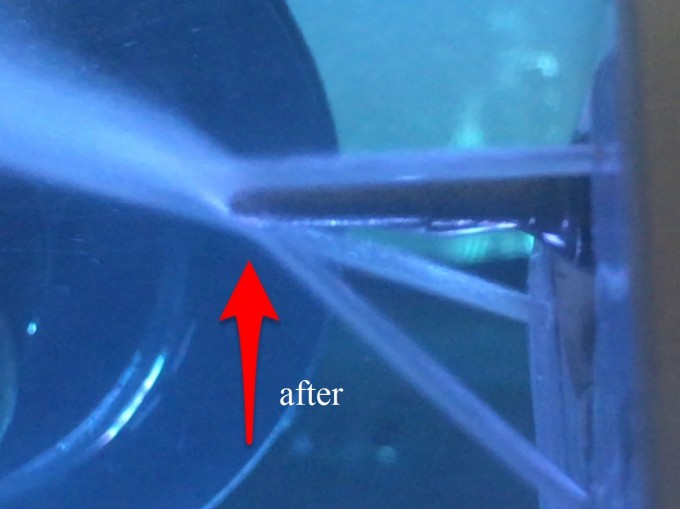

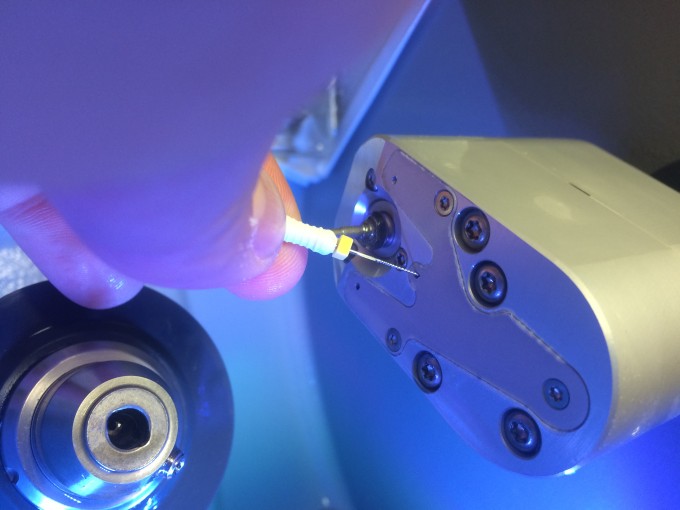

- Close the lid and hit the pump button. This will purge the water through the jets and let you see if water is coming out of all 3 ports. In the pic I have included, you can see water is coming out of all 3 but the tech told me that I had a few that were not firing water to the tip of the bur.

- Once you determine which ports may be clogged, get a 15 or 20 new endo file and insert into each individual port. You can see by the pic that there is a definitive angle you need to get to insert the file properly into the port. Do this with each clogged port and then try the pump button. Repeat until all ports are clear and freely flowing.

He recommended doing this weekly when we change the water to make sure it stays clear and free flowing. I now have my mcxl and omni with new filters, cleaned, calibrated and ready to take on whatever I can bring it. Thanks again Patterson for you service and knowledge with this technology!

On 7/6/2015 at 8:40 am, Shawn Sharp said...Is that crown down or step back technique?

Thanks Rich!

Sharpie

sargenti

Good tip Rich

But I would not use an endo file. In fact I thought it was not recommneded by sirona to use an endo file. I think their fear is the orafice will distort over time if an endo file is used

I use some ortho wire in the same manner

On 7/6/2015 at 8:45 am, Peter Gardell (Faculty) said...Good tip Rich

But I would not use an endo file. In fact I thought it was not recommneded by sirona to use an endo file. I think their fear is the orafice will distort over time if an endo file is used

I use some ortho wire in the same manner

Pete, I agree about the endo file. Possibility of damage. I have been told by the techs here to use a soft bristle tooth brush to clean the ports. Main thing, keep them clean.

![]()

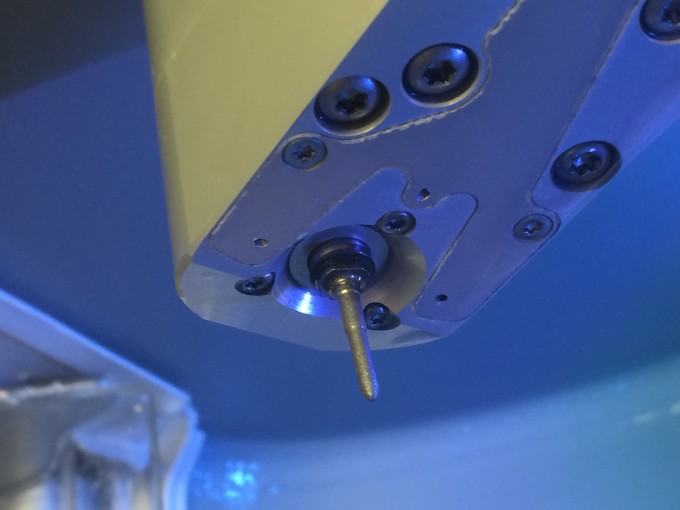

It's not the easiest thing in the world to do but your tech should really remove these 3 Torx screws and take off that front panel. The amount of crap that builds up there is incredible! Using the endo files or the ortho wires just pushes the gunk back into the ditches of the panel - it doesn't actually let it escape. The biggest issue with removing the panel is the clear silicone gasket that tears as soon as you look at it.

On 7/6/2015 at 8:58 am, Ray Morse said...It's not the easiest thing in the world to do but your tech should really remove these 3 Torx screws and take off that front panel. The amount of crap that builds up there is incredible! Using the endo files or the ortho wires just pushes the gunk back into the ditches of the panel - it doesn't actually let it escape. The biggest issue with removing the panel is the clear silicone gasket that tears as soon as you look at it.

he did do that ray. just was showing me what to do in case it got clogged or preventatively to stop it. I'll look into ortho wire or a brush that will fit it

My jets are free flowing but some of them don't hit directly on the tips of the burs. Can I adjust that or does the tech need to do that?

On 7/6/2015 at 9:44 am, Adam Langan said... My jets are free flowing but some of them don't hit directly on the tips of the burs. Can I adjust that or does the tech need to do that?

Adam, as I understand it, there is no adjusting. The ports need to be cleaned. Once cleaned, they "hit" where they are supposed to.

![]()

On 7/6/2015 at 10:07 am, Mark Fleming (Faculty & Magazine Editor) said...On 7/6/2015 at 9:44 am, Adam Langan said... My jets are free flowing but some of them don't hit directly on the tips of the burs. Can I adjust that or does the tech need to do that?Adam, as I understand it, there is no adjusting. The ports need to be cleaned. Once cleaned, they "hit" where they are supposed to.

I asked this exact question and the answer mark gave is what I was told by the tech

the little wires for cleaning the spray ports on a handpiece work nicely, as does Tulsa dentsply's endo activator

On 7/6/2015 at 11:14 am, Marc Thomas said...the little wires for cleaning the spray ports on a handpiece work nicely, as does Tulsa dentsply's endo activator

+1 These little tools that come with handpieces and are perfect for this. I was told an endo file could cause small scraches and allow the port to clog more easily. Great tip on cleaning Rich.

Thanks for sharing,

Justin

On 7/6/2015 at 10:40 am, Richard Rosenblatt said...On 7/6/2015 at 10:07 am, Mark Fleming (Faculty & Magazine Editor) said...On 7/6/2015 at 9:44 am, Adam Langan said... My jets are free flowing but some of them don't hit directly on the tips of the burs. Can I adjust that or does the tech need to do that?Adam, as I understand it, there is no adjusting. The ports need to be cleaned. Once cleaned, they "hit" where they are supposed to.

I asked this exact question and the answer mark gave is what I was told by the tech

i have cleaned these ports with an endo file that was suggested and was able to rotate the ball port so that the stream would the tip of the bur. I think the ortho wire makes better sense.

I started doing this few months ago have file in each mill unit it will make your burs last longer and motors last longer It works its a GREAT TIP,,,,,......Rich thanks for posting!!!!!!!!!!!!!!!!!

Thanks Rich,

this tip went around a few years back, and someone from Europe mentioned he uses CLR and runs a special run of it through with the pump every so often to clean out the jets. This always intrigued me, but I don't have the guts to do it myself as I worry about the seals. Anyone ever try this?

Ive been wanting to take the ports off like Ray mentioned, but am afraid of the seals. Maybe I'll just have my tech do it.

We use the port uncloggers that come with the hand pieces. Every once in a while we need to use endo files, you can actually feel a piece of scale, like calculus that you have to break through.

Anyhoo, glad it's brought up. I think cleaning it should be part of the yearly maint schedule through Patterson.

Lindell

I do agree with Mark, a soft bristle toothbrush once a week is the way to go. No concern for damage or putting fine scratches inside the ports. Maintenance is key. As long as the patterson tech takes it all apart and cleans the buildup underneath the panel once a year, I think you'll be set. CLR is just too corrosive for those seals. Great topic guys.

my cerec specialist recommends standard paper clips. they have the exact size of the orifices and do not harm them. that seems to be the sirona recommedation too.

On 7/6/2015 at 11:14 am, Marc Thomas said...the little wires for cleaning the spray ports on a handpiece work nicely, as does Tulsa dentsply's endo activator

These are perfect.

Rich....I just want to thank you for reminding me that there are indeed 3 water ports on each motor. Apparently since our water tank issue one port on each motor became completely clogged. I was able to free them up with an explorer and endo file like you mention. Now it seems like the mill runs even quicker than it did before.

Rich,

Thanks for reminding me about this tip. I checked and had two of the three ports spraying off into nowhere and now is all good.

Much obliged.

Joel

We also have several pointed burs only lasting a few mills. Ran the pump and noticed one wasn't hitting the tip, did the wire cleaning as sugessted and now it hits it directly. Hopefully this will result on longer lasting burs! Thanks for the advice.